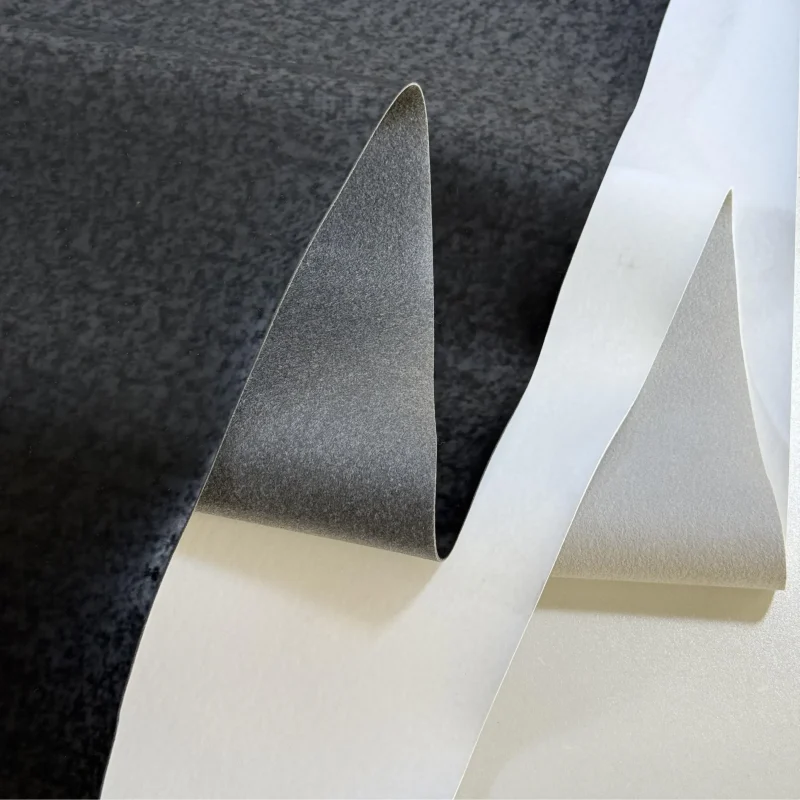

If a customer receives EVA 1.5mm material but measures around 1.2mm, is it a product defect—or a measurement tool/method issue? This case study shows how we closed the loop with standardized re-testing, clear explanations, and photo/video evidence, avoiding unnecessary returns and claims.

Background

A customer from Argentina placed an order for 1.5mm EVA material, total quantity 10,000 meters. After receiving the shipment, the customer measured the thickness using their own gauge and reported readings around 1.2mm, which raised a serious concern about compliance with the agreed specification.

Customer Concerns

-

Fear of non-conforming goods: A 1.2mm reading could impact downstream processing and product performance.

-

Conflicting measurement results: Different readings created uncertainty, extra communication cost, and potential production delays.

-

Need for reliable evidence: The customer required a clear, repeatable measurement process—not just verbal reassurance.

Our Immediate After-Sales Response (SOP)

Once we received the feedback, we activated our internal after-sales process and closed the loop in three steps:

-

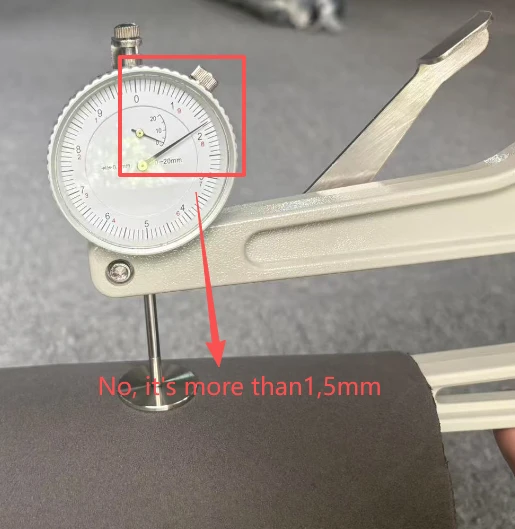

Sampling & measurement-condition verification

We checked retained bulk samples and clarified the customer’s measurement method (pressure, probe type, position, timing, and material compression behavior). -

Re-testing with a dedicated EVA thickness gauge

EVA is elastic and compressible. If a gauge is not suitable (insufficient precision, inconsistent pressure, or mismatched probe structure), readings can deviate significantly.

Using our professional EVA thickness measuring instrument, we re-tested bulk samples from the same production batch and confirmed:-

Thickness was consistently above 1.5mm

-

Results were stable and aligned with the order specification

-

-

Visual proof + clear explanation

We documented the entire re-test procedure with photos and videos (including gauge readings, step-by-step testing, and sample positions). We explained that:-

The customer’s gauge had precision and suitability limitations

-

EVA requires a proper testing setup, otherwise compression can lead to lower apparent thickness readings

-

Outcome

-

After reviewing our photo/video evidence, the customer agreed the issue was caused by measurement-tool limitations and method differences, not by product quality.

-

The concern was resolved smoothly, preventing unnecessary returns or claims and supporting continued cooperation.

What We Standardized from This Case

To reduce similar disputes, we now proactively support customers with:

-

Recommended measurement guidelines (pressure/probe, sampling positions, repetitions, recording template)

-

Third-party verification support when required

-

Batch sample retention & traceability for fast re-checking

-

Customizable specifications for thickness, width, and performance as needed

Why Ningbo Dolphins

We work closely with Latin American clients and understand what matters most: stable quality, reliable delivery, and fast after-sales support. When data conflicts happen, we solve them with standardized testing and visual evidence, so customers can use materials with confidence.

If you face EVA thickness disputes or need a clear testing reference, contact us for:

measurement guidance + benchmark testing process + batch traceability support